In recent years, the field of catalysis has undertaken transformative advancements, especially with iron and copper-based stimulants. The effectiveness of methanol synthesis drivers is critical, and their performance can be assessed based on numerous parameters such as activity, selectivity, and lasting security.

Among the vital elements in methanol manufacturing, copper-based stimulants hold a significant position. Their capability to facilitate the conversion of carbon dioxide and hydrogen right into methanol is especially important in the context of lasting power techniques. As the globe faces climate change, the look for reliable catalytic procedures that minimize greenhouse gas discharges is much more urgent than ever. Copper catalysts demonstrate excellent efficiency in methanol synthesis, greatly as a result of their positive electronic properties and high surface, which boost the communication with reactant molecules.

Regardless of their benefits, one must take into consideration the economic facets of these drivers. The price of methanol synthesis stimulants is an essential problem for sectors wanting to optimize manufacturing costs. Aspects influencing catalyst prices consist of the price of resources, the intricacy of the synthesis process, and the demand-supply equilibrium in the market. The marketplace for these catalysts has actually been evolving, with manufacturers and distributors making every effort to deliver high-performance items at competitive costs to fulfill the growing need for methanol and methanol-derived products.

Catalyst deactivation remains a vital problem in methanol synthesis. Gradually, catalysts can shed their efficiency because of elements like carbon, sintering, or poisoning deposition. The deactivation of methanol synthesis stimulants postures challenges for commercial applications, as it impacts the overall performance of the process and enhances functional expenses. Study efforts are continuously directed towards understanding the devices behind catalyst deactivation. Approaches to regenerate or stabilize these drivers are likewise being discovered to extend their lifetimes and preserve high levels of activity. Therefore, advancement in catalyst layout and regrowth strategies is essential for meeting the future needs of the methanol market.

In addition to copper drivers, iron-based stimulants have additionally been historically used in methanol synthesis procedures. The mix of iron and copper in bimetallic catalysts is an interesting method gaining traction, as it aims to harness the toughness of both steels to improve reaction rates and selectivity in methanol synthesis.

Could this procedure be even more accelerated with details drivers? Yes, especially with the usage of extremely active methanation stimulants that enhance the conversion efficiency and selectivity towards methane.

CO2 methanation stimulants play a vital function in transforming CO2 exhausts into helpful power resources. The development of CO2 methanation drivers includes the mindful selection of active materials, with nickel, cobalt, and also cerium-based stimulants being explored for their potential effectiveness in this application.

Zinc oxide desulfurization stimulants also represent an essential segment of catalyst study. Desulfurization is essential for the synthesis of tidy gas and chemicals, as sulfur can toxin numerous catalysts, leading to significant losses in task.

The rise of catalytic converters, specifically carbon monoxide (CO) converters, highlights the need for drivers capable of assisting in reactions that provide hazardous exhausts harmless. These converters make use of rare-earth elements such as platinum, palladium, and rhodium as energetic components. Their duty in automobile applications emphasizes the value of catalysts in enhancing air quality and lowering the ecological impact of vehicles. The developments in catalyst modern technologies continue to improve the functionality and life expectancy of catalytic converters, giving solutions to satisfy rigorous emissions policies worldwide.

While conventional drivers have actually prepared for modern-day application, brand-new opportunities in catalyst growth, consisting of nanoparticle modern technology, are being discovered. The one-of-a-kind residential properties of nanoparticles-- such as high area and one-of-a-kind digital characteristics-- make them incredibly assuring for boosting catalytic activity. The integration of these novel products right into methanol synthesis and methanation procedures might potentially reinvent them, resulting in more efficient, lasting manufacturing pathways.

The future landscape for methanol synthesis catalysts is not only concerning boosting catalytic residential properties but also integrating these advancements within more comprehensive renewable resource methods. The coupling of eco-friendly power sources, such as wind and solar, with catalytic processes holds the possibility for creating an incorporated eco-friendly hydrogen economy, in which hydrogen produced from eco-friendly sources acts as a feedstock for methanol synthesis, shutting the carbon loop.

As we look in the direction of the future, the shift towards greener modern technologies will undoubtedly improve the catalysts utilized in industrial processes. This recurring evolution not only uses financial get more info advantages however additionally aligns with international sustainability goals. The catalytic technologies that arise in the coming years will undoubtedly play a vital role in shaping power systems, thus highlighting the ongoing value of research and advancement in the area of catalysis.

To conclude, the landscape of drivers, particularly in the context of methanol check here synthesis and methanation processes, is rich with challenges and possibilities. From iron and copper-based materials to innovations in catalysts developed for CO2 conversion, the advancements in this area symbolize a dedication to boosting performance and sustainability. As industries and researchers continue to innovate and resolve catalyst deactivation and prices, the press for greener and extra effective chemical procedures advantages not just manufacturers yet additionally the international area pursuing a lasting future. As we depend on the verge of a shift in the website direction of an extra carbon-neutral globe, the development of these drivers will play a pivotal duty in attaining long-lasting energy goals.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Gia Lopez Then & Now!

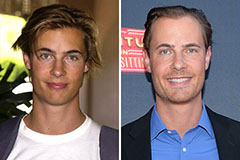

Gia Lopez Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!